Applying Athletic Training Principles in the Industrial Setting

An Interview with Marty Matney, MBA, ATC, PTA\Program Manager for Work-Fit

Information provided by Mr. Matney in this interview are his personal opinion and does not constitute an endorsement by Work-Fit, our parent company or any of our corporate clients.

Marty Matney oversees a staff of twenty-two (22) athletic trainers delivering Work-Fit services onsite to over 18,000 workers in Everett, Washington.

Work-Fit is the nationwide leader in managing on-site fitness, wellness, injury prevention, treatment and rehabilitation programs; directed towards the reduction of musculoskeletal issues encountered in the work environment. Their philosophy approaches the corporate/occupational worker as an athlete because the occupational athlete has many of the same physical demands as a traditional athlete. In this way they deliver the same level of care afforded a professional athlete to keep them healthy and in the game.

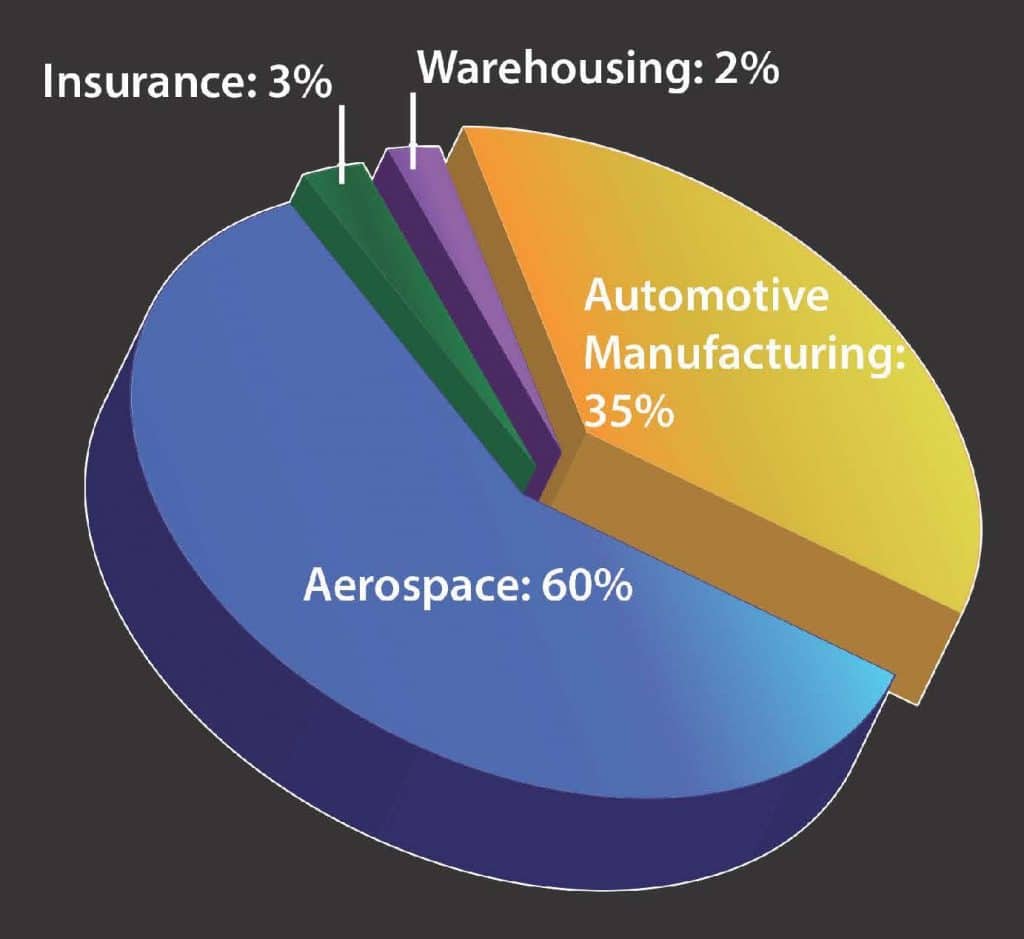

Work-Fit manages 20 sites in 10 states from Rhode Island to Washington serving over 50,000 client employees. All revenues come from worksite services, broken up into:

- Automotive Manufacturing: 35%

- Aerospace: 60%

- Insurance: 3%

- Warehousing: 2%

By cross-utilization of highly trained staff, state-of-the-art fitness and wellness equipment, Work-Fit increases its effectiveness in getting employees healthy and keeping them healthy.

We asked Marty about the unique challenges of this work environment.

Q: What are the most common conditions you address in this setting?

The most common conditions are musculoskeletal conditions from repetitive use/repetitive trauma, positional exertion, biomechanical stresses due to body positioning or ergonomic conditions related to tooling. Conditions like muscle spasms and strains, trigger points and general muscle fatigue. Areas often involved include the back (erector spinae group), the shoulder and neck and the upper extremity. Occasionally we see long-term overuse conditions involving joints.

Q: Is it ever a challenge to balance the desire of the employer to keep the worker on the job with your ultimate wellness goals?

Yes. Most often production goals take precedence over wellness. The employer sets the goals and the employees strive to achieve them. However, throughout America both the employer and employee realize the importance of wellness and are beginning to initiate programs throughout manufacturing to address this. Obviously, the employer’s overlying goal is to reduce costs associated with health-related issues and maintain a productive workforce. As they slowly realize that a healthy workforce is a productive workforce, they are learning to balance wellness with production. Once a company commits to a wellness plan, a challenge is to get employee buy-in to the concept of wellness. The “We’ve been doing it like this for years” mentality calls for a paradigm shift which is difficult to achieve in a world where routine is routine. Here is where the athletic trainer and other on-site health personnel are effective and can influence change. From consistent contact, intelligent solutions to quickly address problems and follow-through aimed at affecting change, employers are readily seeing a return on their investment in reduced time-loss injuries and, more importantly, employees are realizing positive outcomes in their ability to perform their jobs and enjoy time away from work without being hampered with pain associated with work. A wellness program involves commitment and buy-in from all parties – employers and employees. If this is achieved, everyone wins. The employer wins with reduced healthcare costs and decreased employee absence and the employee wins by staying on the job and quality of life improvements. In many instances, the athletic trainer on the ground and company wellness personnel are the heroes because they make it happen.

Q: What made you realize that this combination of athletic and wellness goals would be so successful in the industrial setting?

Just like in athletics, workers in the industrial setting are a team. They both have the same goals – to produce positive results, whether it be contributing to wins or contributing to the company’s purpose. Many times the effort is very similar. It is tough, physical work that places maximum stresses on the body for long periods. The main difference though is that in athletics, there is more running around but it’s for only 3 hours a day. In industry, there is no running, but the stresses placed on the body are for 9, 10+ hours per day. The injuries athletic trainers see in industry are similar to those in athletics except for fewer broken bones, blown-out knees and concussions (if any.) Otherwise, the body is the body. If you place maximum stresses on it for long enough time, it will begin to break down. It doesn’t matter if that happens in industry or in athletics. The job of the athletic trainer in industry is just like their job in athletics – keep the team going, injury-free and once hurt, get them back as quickly and safely as possible and do your best to prevent injuries from occurring in the first place. A worker that is in less pain is more productive…not only at work but in their life-enjoyment activities. That leads to better morale, which in turn leads right back to a happier more productive worker. That equals a win for everyone!

Q: What is the time percentage breakdown between trouble-shooting injuries or physical complaints and maintaining everyday total wellness? Does this change over time as the employees become used to your program?

In the industrial setting, athletic trainers are the boots on the ground. We interface with the employees and managers to analyze the “root cause.” What is the cause of the injury or injuries? Once an injury or a series of injuries occur, athletic trainers are often the healthcare professional who is there to trouble-shoot cause. Often the athletic trainer works with other professionals such as ergonomists or health and safety personnel to analyze and affect change. It is often the role of the athletic trainer to work with managers, employees and safety personnel to implement injury prevention strategies derived from the root cause analysis. From a time-percentage aspect, there is often an evolution or a cycle that takes place. An injury is identified, an analysis of the cause is conducted, injury prevention solutions are developed and implemented and consistent follow-up is conducted to insure compliance. Over time, it does evolve where the employee will often initiate the concern and seek help in injury prevention and initiate participation in their own wellness.

Q: How does Kinesio Taping fit into the plan? What other techniques or modalities are most useful, and why?

Kinesio Taping has become an essential tool in our toolbox in the industrial setting. With the need to get employees back on the job, much like in athletics, proper application of Kinesio Tape by trained practitioners has become an essential technique that provides immediate results. It fits into the model of OSHA (Occupational Safety and Health Administration) level first aid as non-rigid support and has become a modality sought out by those we work with. Typically, when we have musculoskeletal conditions, such as spasm or strains and edema, they are evaluated by an athletic trainer to determine the severity and appropriate course of care. In many cases, the athletic trainer uses Kinesio Tape to address the employee’s condition and universally has positive results. It is the perfect adjunct for the athletic trainer to provide service to those who will benefit. Other modalities we use in this setting include ice, manual techniques such as myofascial release, muscle energy, Active Release Technique, among others, and athletic taping. Kinesio Tape has become a cornerstone in our care strategies for our employees. A primary cause of many of the musculoskeletal issues we see arise from postural deficiencies. Kinesio Tape has made addressing these deficiencies much easier and effective as we can now have workers strengthen muscle groups from a better anatomical position rather than trying to just get back to neutral.